Project Description

PRODUCT INFORMATION

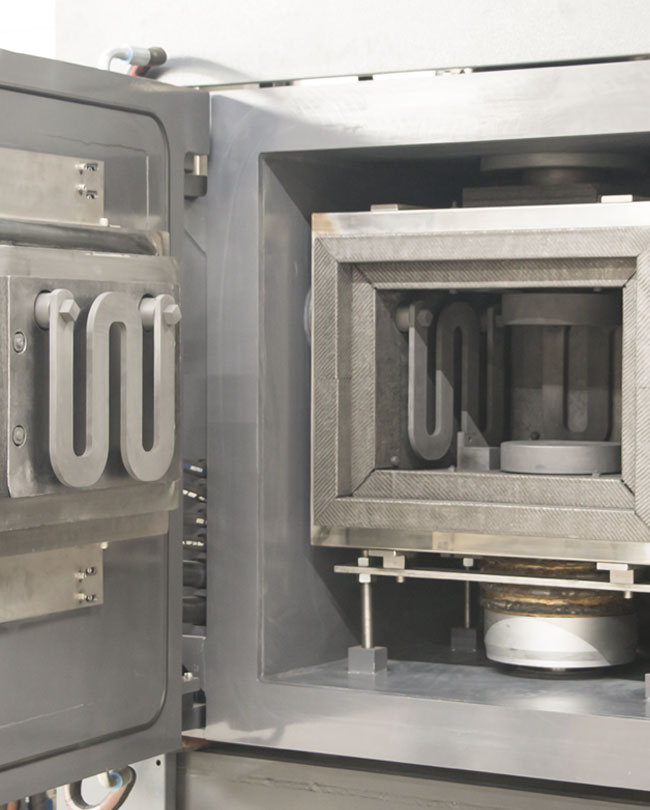

MSE Furnace is produced atmosphere controlled automatic hot press in accordance with the new requirements in the field of industry, Research and Development.

Atmosphere controlled automatic hot press can making pressing and heating at the same time. Also, it has the vacuuming feature for the sweeping purpose. The whole process can be monitored on the touch screen and recorded via USB.

Pressing, which is one of the most widely used methods of material shaping methods, has been designed to design different presses according to the basic requirements of the application.

MSE Furnace produces various press-driven presses with various characteristics in accordance with the new requirements in the field of technology, industry and R&D. Apart from the standard specifications, a number of presses are designed and manufactured for the purpose of the process use.

STANDARD FEATURES

PID controlled heating, PLC control and touch screen, force, time, temperature and position control, adjustable stroke distance, displaying and save process log display, data recording with USB port and the ability to automatically adjust and program the vacuum and pressing operation via touch screen, Error display in case a breakdown, Observation of set and real temperature

Electronic safety system, emergency stop button, System protection for over temperature, audiovisual warning alarm, auto power cut while the lid is opens

Force control via patented MSE_Servo Hydraulic system

Atmosphere controlled cooled cabin, cooling temperature display

Load cell

Can be pressed likewise every time

Galvanized steel construction

Able to work at maximum temperature

Over temperature alarm

Epoxy shippimer coated

Hydraulic pump and hydraulic system protection

High sensitivity at low flow

Inert gas inlet and adjustable gas flow meter

- Temperature measurement via the thermocouple

Do not able to work without lid closed

10-2 mbar vacuum pump and vacuum display

Water circulated hydraulic system protection

OPTIONAL FEATURES

(CH) Chiller

(K) Mould for press

(GR) Graphite blocks and pressure refractories for high temperatures

(DA) Dual-axis pressing

Please follow us on social media for news & events.

UP TO 3000°C